The requirements and desires with regard to design and functionality relate to very different aspects. These include requirements such as low weight, easy assembly, high thermal insulation and burglary resistance. The development of new materials also plays an important role. In various projects with the doors manufacturer Biffar, we create solutions through simulation.

Optimization of Doors by Means of Simulation

Development of New Materials

In the selection of door materials, multiple criteria must be evaluated in a manner similar to that of other industries, such as motor vehicle construction. Additionally, the layer construction of door leaves for special applications must be evaluated. In the process, the great advan tage of simulation techniques over measurement and testing processes is the fact that evaluation is possible without the production of prototypes. In the scope of the project, simulation techniques and evaluation methods were specially developed for the selection of door materials which can be used for the dimensioning and optimisation of doors in regard to thermal insulation, fire protection properties and break-in resistance.

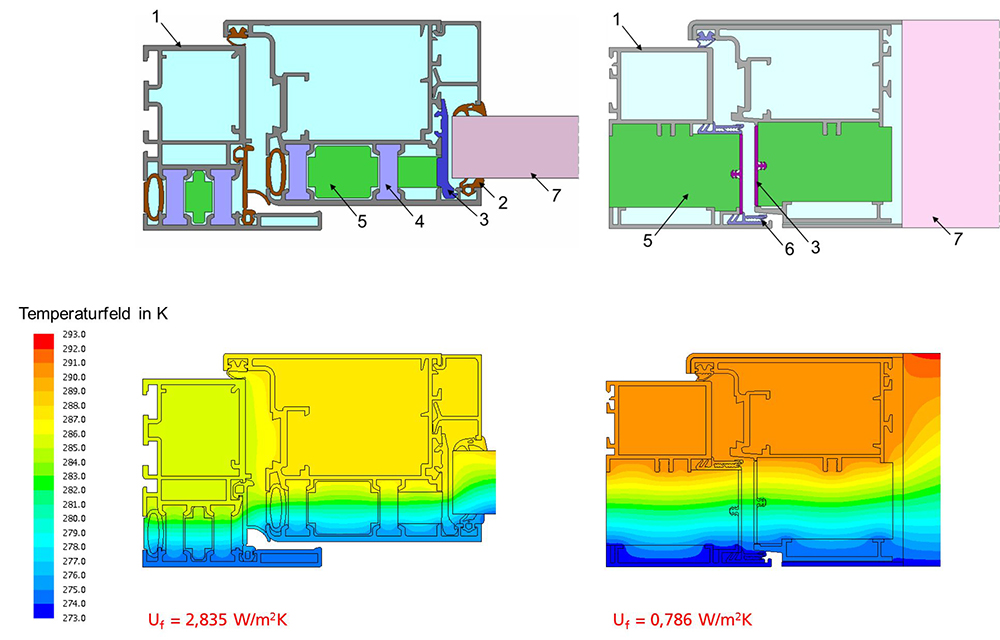

Here, some typical simulation results for door constructions with aluminum profiles are shown, which prevent distortion, which are resistant to breakage and additionally have an attractive surface.

Optimisation of Thermal Insulation

An important focus of the simulation is the optimization of the thermal insulation properties, which are characterized by the U-value (heat transfer coefficients) in the construction industry. The U-value of the entire door structure consists of the U-values of the door leaf, the door frame and the frame.

In order to also prepare the company Biffar for changing requirements and new markets, it was provided with software tools developed at the Fraunhofer ITWM and its employees were trained in its use. A software tool which is now in use automatically calculates the heat transfer coefficient of the door in accordance with DIN EN ISO 6949 on the basis of the door design (door height, width, frame) and the construction of the door leaf. In this manner it can be ensured that the current requirements on thermal insulation are already fulfilled during the design process.

Figure 1 shows the simulation results of the U values for two versions of aluminum profiles (material 1) for the door and the frame. The insulation material is characterized as material 2. The corresponding temperature fields show the stationary state at a temperature difference of 20 Kelvin. Although the thickness of the frame and the material insert have hardly been increased, the optimized variant (Fig. 1, right) has a significantly lower U-value.

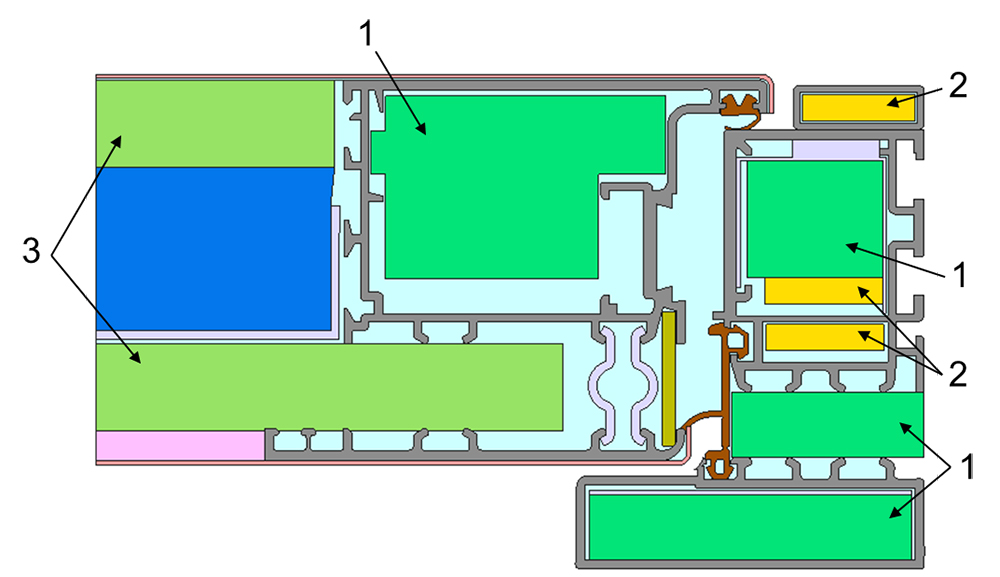

Calculation of Fire Resistance

A second simulation focuse is the calculation of the fire resistance, as fire tests are very complex and expensive. Some of the tests for the detection of fire resistance in the customer's country and must not be carried out in the country.

The effect of the frequently used fire protection materials (materials 1, 2 and 3 in Figure 2) is based on one or more phase transformations in the material, which require large amounts of heat energy. Consequently, the phase transformation processes must be described in the modeling and simulation.

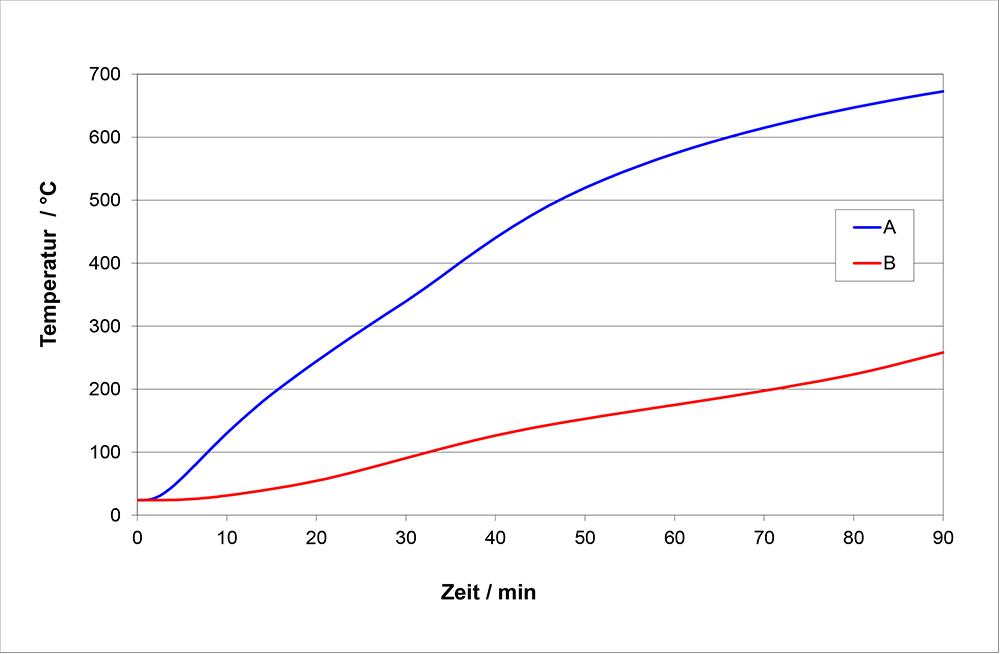

The results of the simulation of a fire test, which is standardized, are shown in Fig. 3. The maximum temperature shown on the diagram on the side facing the fire is significantly lower in the optimized variant over the entire period than in the conventional profile. This example also demonstrates the great potential for optimization, which has been exhausted by the simulation of a variety of variants.

Evaluation Burglar Security and Wind Load

The results of standard FEM simulations for stress analysis were used to assess the bulgar security and wind load.The burglary resistance is examined by means of local pressure loads on different points of the door surface.

This makes it possible to optimize the materials as well as the wall thicknesses, whereby it must be taken into account that lighter doors are advantageous both during assembly and as regards opening and closing functions.

Tests Confirm Simulation Results

The simulation results presented here were confirmed in real tests and tests with high accuracy. Furthermore, without such FEM simulations such an optimization of doors and frames would not have been possible in such a short time.

Through our successful collaboration with Biffar, the Biffar designers were able to take the results of FEM simulation directly into the product design and thus the optimization potential use. This has convinced the responsible persons at Biffar that the simulation has become a routine in new door structures.