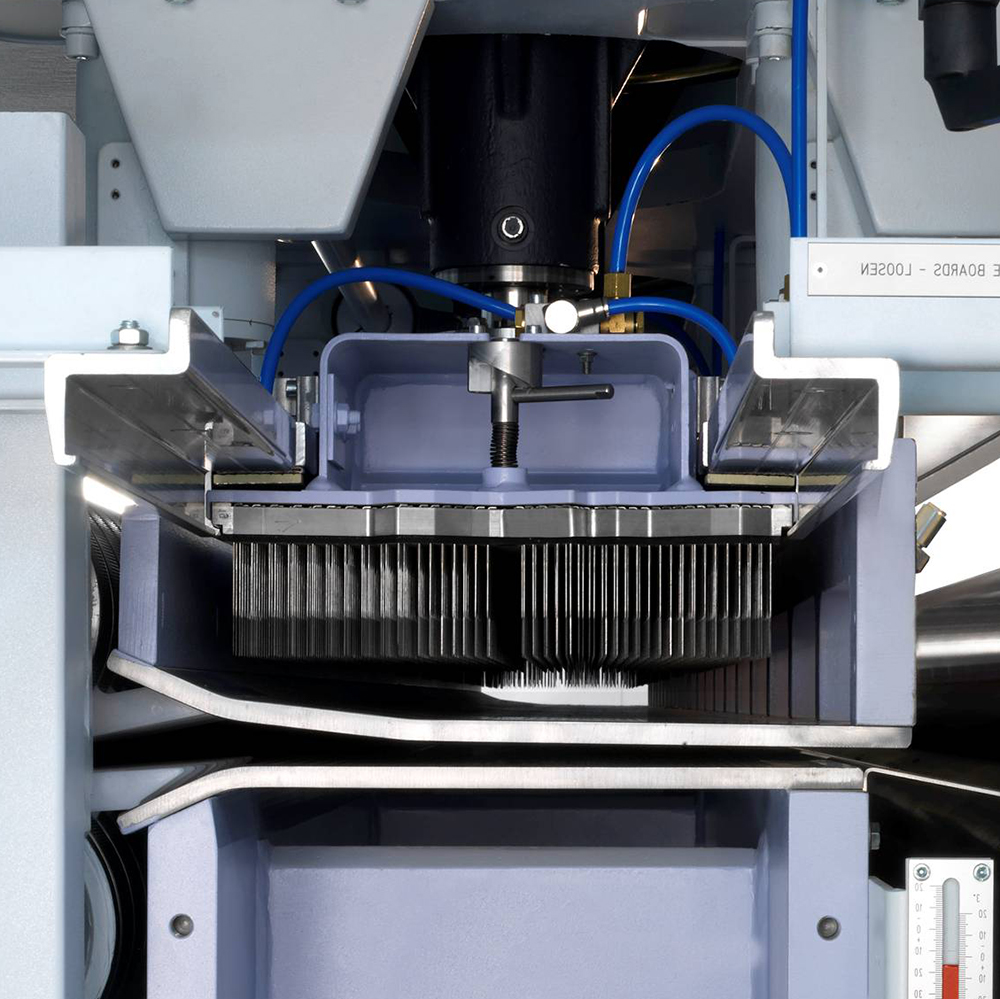

Needle punching is a well-established method to bond nonwovens mechanically. In this process thousands of barbed needles penetrate simultaneously into the nonwoven. Hereby, fibers captured by a needle are drawn through the layers of the nonwoven to solidify them. The resulting properties of the needle punched nonwoven depend significantly on the machine and process parameters: needle density, needle arrangement, feed per stroke and belt speed.

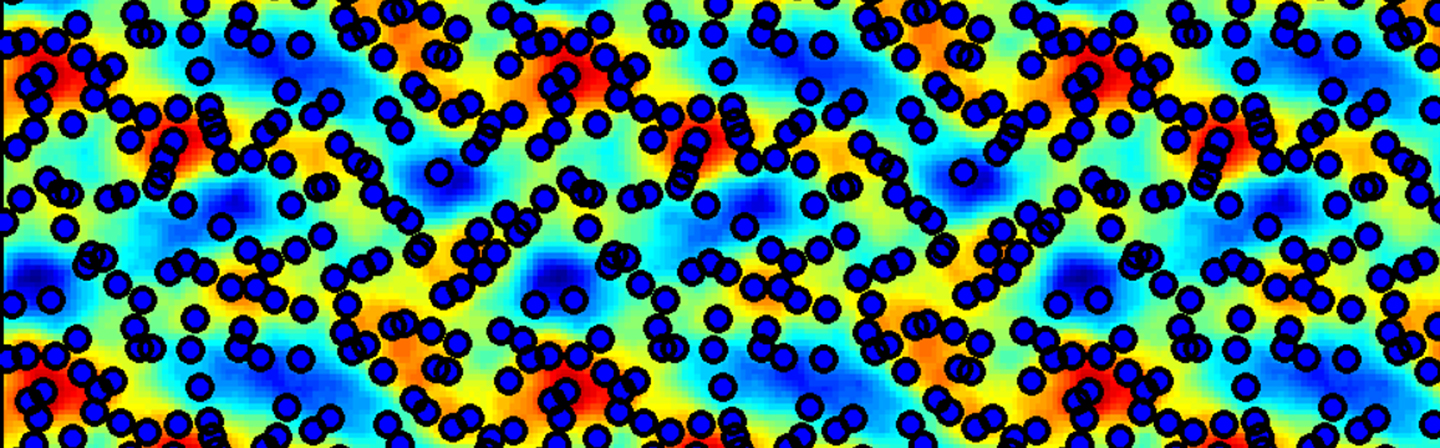

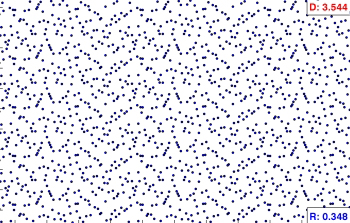

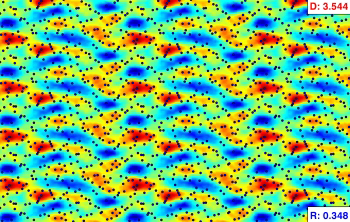

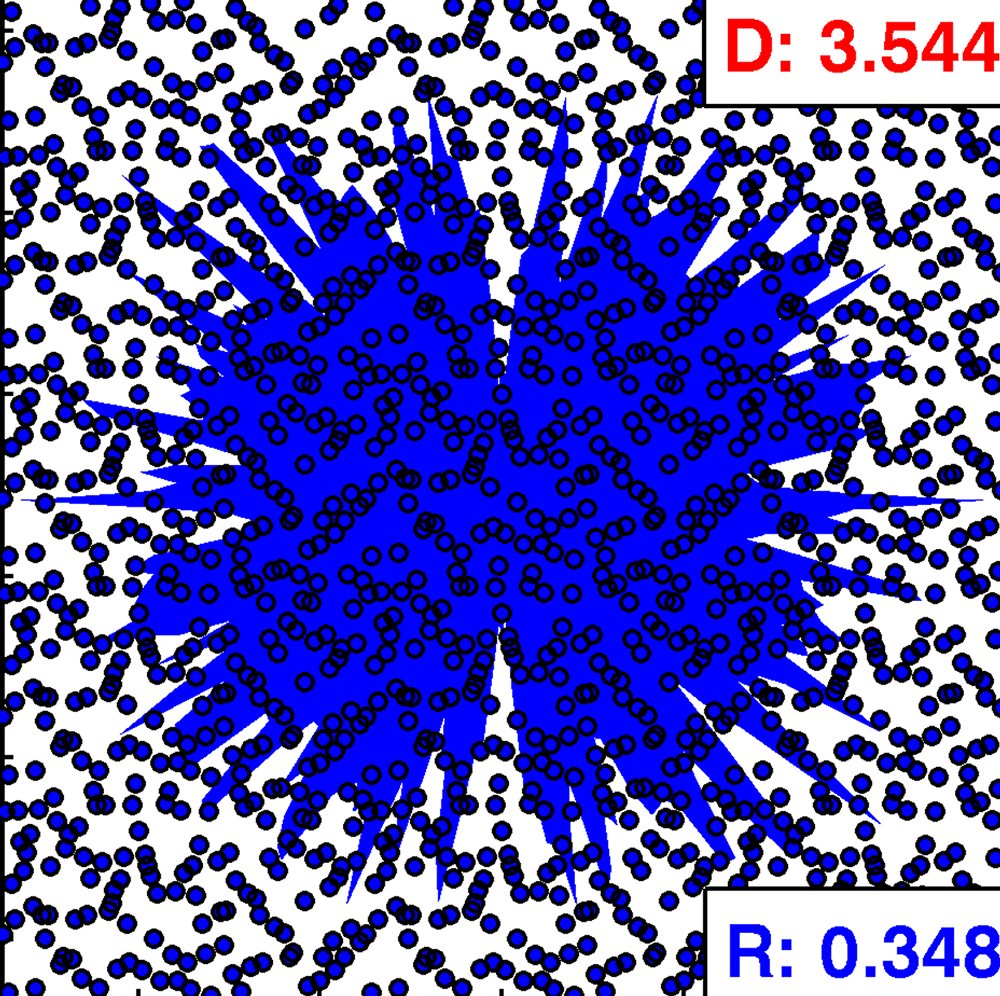

One measure of quality is based on the number of needle punches per area which should be as homogeneous as possible. Any kind of stripes in vertical, horizontal or diagonal direction caused by structures in the needle punch pattern should be avoided. Fraunhofer ITWM has developed in close cooperation with Oerlikon Neumag Austria a software tool to simulate the needle punch pattern and optimize the positions of the needles in the board according to specified process settings.